Заказы, оплаченные до 12:00 МСК, отправляем в день оплаты, после 12:00 - отправляем на следующий день.

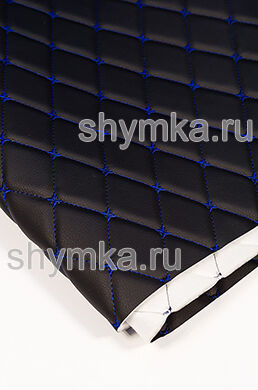

Экокожа стеганая Ромб декоративный - купить в розницу и оптом

|

Экокожа Орегон на поролоне 5мм на спанбонде

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на черном

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на спанбонде

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на черном

есть на складе данная позиция также представлена с перфорацией нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 10мм на черном

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон ПЕРФОРАЦИЯ на поролоне 5мм

есть на складе данная позиция также представлена без перфорации КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на черном

есть на складе данная позиция также представлена с перфорацией нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон ПЕРФОРАЦИЯ на поролоне 5ммна черном спанбонде 60г/кв.м ЧЕРНАЯ стеганная

есть на складе данная позиция также представлена без перфорации нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на черном

есть на складе данная позиция также представлена с перфорацией нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон ПЕРФОРАЦИЯ на поролоне 5мм

есть на складе данная позиция также представлена без перфорации КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на черном

есть на складе данная позиция также представлена без перфорации нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон ПЕРФОРАЦИЯ на поролоне 5ммна черном спанбонде 60г/кв.м ЧЕРНАЯ стеганная

есть на складе данная позиция также представлена без перфорации нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на черном

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на спанбонде

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на черном

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на спанбонде

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на черном

есть на складе данная позиция также представлена с перфорацией нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 10мм на черном

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон ПЕРФОРАЦИЯ на поролоне 5мм

есть на складе данная позиция также представлена без перфорации КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на спанбонде

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на черном

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на спанбонде

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на черном

есть на складе данная позиция также представлена с перфорацией нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 10мм на черном

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон ПЕРФОРАЦИЯ на поролоне 5мм

есть на складе данная позиция также представлена без перфорации КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на черном

есть на складе данная позиция также представлена с перфорацией нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 10мм на черном

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон ПЕРФОРАЦИЯ на поролоне 5мм

есть на складе данная позиция также представлена без перфорации КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на графитовом

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на графитовом

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на графитовом

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на графитовом

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на сером

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на сером

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на сером

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на бежевом

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон ПЕРФОРАЦИЯ на поролоне 5мм

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на бежевом

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон ПЕРФОРАЦИЯ на поролоне 5мм

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на бежевом

на складе 7 пог.м, приход ожидается в конце апреля нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на белом

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон ПЕРФОРАЦИЯ на поролоне 5мм на белом

на складе 22,10 пог.м, выводим из ассортимента нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на белом

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на белом

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на белом

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на коричневом

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на коричневом

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на коричневом

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на коричневом

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на коричневом

есть на складе данная позиция также представлена с перфорацией нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон ПЕРФОРАЦИЯ на поролоне 5мм

есть на складе данная позиция также представлена без перфорации нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на спанбонде

есть на складе нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон на поролоне 5мм на коричневом

есть на складе данная позиция также представлена с перфорацией нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Экокожа Орегон ПЕРФОРАЦИЯ на поролоне 5мм

на складе 30,5 пог.м, выводим из ассортимента данная позиция также представлена без перфорации нитки, используемые в стежке, можно купить отдельно здесь КРАТКИЕ ДАННЫЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

ОПИСАНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

ПРИМЕНЕНИЕ СТЕГАННОЙ ЭКОКОЖИ НА ПОРОЛОНЕ НА ПОДЛОЖКЕ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

УХОД ЗА ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ НА ПОРОЛОНЕ С ПОДЛОЖКОЙ: |

||||||

|

|||||||

|

Каталог Стеганая Экокожа РОМБ-1

есть на складе размер образцов 100х150мм, 9 образцов, скреплены стяжкой, подписаны каталог отправляется хорошо запакованным в воздушно-пузырьковую пленку и коробку на каталоге нет никакой информации (название, телефон, адрес) о компании www.SHYMKA.ru С помощью каталога можно в живую подобрать нужный Вам материал. Также каталог позволяет продавать материалы под заказ. Просто киньте каталог в корзину и оформите заказ с доставкой в Ваш город. После получения каталога, подберите нужный Вам материал и аналогично оформите заказ. Каталог включает в себя:

|

|

Каталог Стеганая Экокожа РОМБ-2

есть на складе размер образцов 100х150мм, 9 образцов, скреплены стяжкой, подписаны каталог отправляется хорошо запакованным в воздушно-пузырьковую пленку и коробку на каталоге нет никакой информации (название, телефон, адрес) о компании www.SHYMKA.ru С помощью каталога можно в живую подобрать нужный Вам материал. Также каталог позволяет продавать материалы под заказ. Просто киньте каталог в корзину и оформите заказ с доставкой в Ваш город. После получения каталога, подберите нужный Вам материал и аналогично оформите заказ. Каталог включает в себя:

|

|

Каталог Стеганая Экокожа КВАДРАТ НЕО-1

есть на складе размер образцов 100х150мм, 21 образец, скреплены стяжкой, подписаны каталог отправляется хорошо запакованным в воздушно-пузырьковую пленку и коробку на каталоге нет никакой информации (название, телефон, адрес) о компании www.SHYMKA.ru С помощью каталога можно в живую подобрать нужный Вам материал. Также каталог позволяет продавать материалы под заказ. Просто киньте каталог в корзину и оформите заказ с доставкой в Ваш город. После получения каталога, подберите нужный Вам материал и аналогично оформите заказ. Каталог включает в себя:

|

|

Каталог Стеганая Экокожа КВАДРАТ НЕО-2

есть на складе размер образцов 100х150мм, 18 образцов, скреплены стяжкой, подписаны каталог отправляется хорошо запакованным в воздушно-пузырьковую пленку и коробку на каталоге нет никакой информации (название, телефон, адрес) о компании www.SHYMKA.ru С помощью каталога можно в живую подобрать нужный Вам материал. Также каталог позволяет продавать материалы под заказ. Просто киньте каталог в корзину и оформите заказ с доставкой в Ваш город. После получения каталога, подберите нужный Вам материал и аналогично оформите заказ. Каталог включает в себя:

|

|

Каталог Стеганая Экокожа РОМБ ДЕКОРАТИВНЫЙна черном спанбонде

есть на складе размер образцов 100х150мм, 22 образца, скреплены стяжкой, подписаны каталог отправляется хорошо запакованным в воздушно-пузырьковую пленку и коробку на каталоге нет никакой информации (название, телефон, адрес) о компании www.SHYMKA.ru С помощью каталога можно в живую подобрать нужный Вам материал. Также каталог позволяет продавать материалы под заказ. Просто киньте каталог в корзину и оформите заказ с доставкой в Ваш город. После получения каталога, подберите нужный Вам материал и аналогично оформите заказ. Каталог включает в себя:

|

|

Каталог Стеганая Экокожа РОМБ ДЕКОРАТИВНЫЙ

есть на складе размер образцов 100х150мм, 8 образцов, скреплены стяжкой, подписаны каталог отправляется хорошо запакованным в воздушно-пузырьковую пленку и коробку на каталоге нет никакой информации (название, телефон, адрес) о компании www.SHYMKA.ru С помощью каталога можно в живую подобрать нужный Вам материал. Также каталог позволяет продавать материалы под заказ. Просто киньте каталог в корзину и оформите заказ с доставкой в Ваш город. После получения каталога, подберите нужный Вам материал и аналогично оформите заказ. Каталог включает в себя:

|

|

Каталог Стеганая Экокожа РОМБ ДЕКОРАТИВНЫЙ

есть на складе размер образцов 100х150мм, 26 образцов, скреплены стяжкой, подписаны каталог отправляется хорошо запакованным в воздушно-пузырьковую пленку и коробку на каталоге нет никакой информации (название, телефон, адрес) о компании www.SHYMKA.ru С помощью каталога можно в живую подобрать нужный Вам материал. Также каталог позволяет продавать материалы под заказ. Просто киньте каталог в корзину и оформите заказ с доставкой в Ваш город. После получения каталога, подберите нужный Вам материал и аналогично оформите заказ. Каталог включает в себя:

|

|

Каталог Стеганая Винилискожа и Экокожа

есть на складе размер образцов 100х150мм, 6 образцов, скреплены стяжкой, подписаны каталог отправляется хорошо запакованным в воздушно-пузырьковую пленку и коробку на каталоге нет никакой информации (название, телефон, адрес) о компании www.SHYMKA.ru С помощью каталога можно в живую подобрать нужный Вам материал. Также каталог позволяет продавать материалы под заказ. Просто киньте каталог в корзину и оформите заказ с доставкой в Ваш город. После получения каталога, подберите нужный Вам материал и аналогично оформите заказ. Каталог включает в себя:

|