Заказы, оплаченные до 12:00 МСК, отправляем в день оплаты, после 12:00 - отправляем на следующий день.

Экокожа Компаньон - купить в розницу и оптом

|

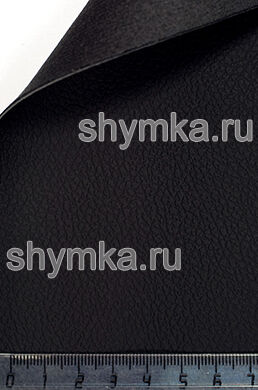

Экокожа Kомпаньон Dakota DK 2101

есть на складе доступен аналог: экокожа на микрофибре Dakota D 2101 КРАТКИЕ ДАННЫЕ ЭКОКОЖИ КОМПАНЬОН:

ХАРАКТЕРИСТИКИ ЭКОКОЖИ КОМПАНЬОН:

ОПИСАНИЕ ЭКОКОЖИ:

ЧЕМ ОТЛИЧАЮТСЯ ЭКОКОЖИ МЕЖДУ СОБОЙ:

ПРИМЕНЕНИЕ ЭКОКОЖИ:

РЕКОМЕНДАЦИИ ПО ПЕРЕТЯЖКИ СИДЕНИЙ ЭКОКОЖЕЙ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ:

УХОД ЗА ЭКОКОЖЕЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ: |

||||||

|

|||||||

|

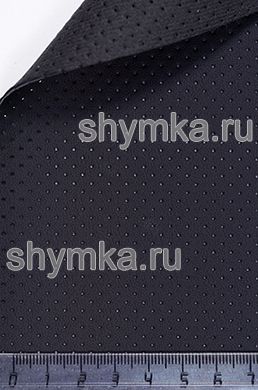

Экокожа Kомпаньон Dakota RK 2101

есть на складе доступен аналог: экокожа на микрофибре Dakota R 2101 КРАТКИЕ ДАННЫЕ ЭКОКОЖИ КОМПАНЬОН:

ХАРАКТЕРИСТИКИ ЭКОКОЖИ КОМПАНЬОН:

ОПИСАНИЕ ЭКОКОЖИ:

ЧЕМ ОТЛИЧАЮТСЯ ЭКОКОЖИ МЕЖДУ СОБОЙ:

ПРИМЕНЕНИЕ ЭКОКОЖИ:

РЕКОМЕНДАЦИИ ПО ПЕРЕТЯЖКИ СИДЕНИЙ ЭКОКОЖЕЙ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ:

УХОД ЗА ЭКОКОЖЕЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ: |

||||||

|

|||||||

|

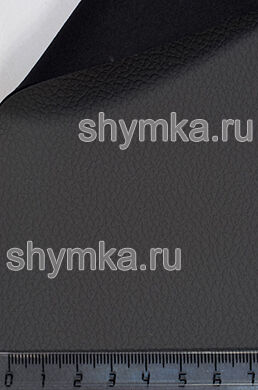

Экокожа Kомпаньон NEW Dakota BLACK

есть на складе по качеству схожа с экокожей Компаньон данная позиция также представлена с перфорацией данная позиция также представлена: на поролоне 5мм данная позиция также представлена: на поролоне с перфорацией 5мм КРАТКИЕ ДАННЫЕ ЭКОКОЖИ КОМПАНЬОН NEW:

ОПИСАНИЕ ЭКОКОЖИ:

ЧЕМ ОТЛИЧАЮТСЯ ЭКОКОЖИ МЕЖДУ СОБОЙ:

ПРИМЕНЕНИЕ ЭКОКОЖИ:

РЕКОМЕНДАЦИИ ПО ПЕРЕТЯЖКИ СИДЕНИЙ ЭКОКОЖЕЙ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ:

УХОД ЗА ЭКОКОЖЕЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ: |

||||||

|

|||||||

|

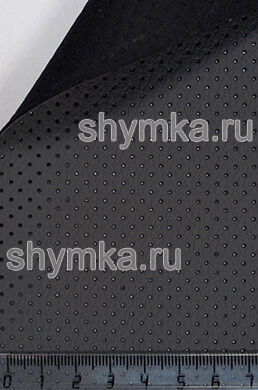

Экокожа Kомпаньон NEW Dakota BLACK

есть на складе по качеству схожа с экокожей Компаньон данная позиция также представлена без перфорации данная позиция также представлена: на поролоне 5мм данная позиция также представлена: без перфорации на поролоне 5мм КРАТКИЕ ДАННЫЕ ЭКОКОЖИ КОМПАНЬОН NEW:

ОПИСАНИЕ ЭКОКОЖИ:

ЧЕМ ОТЛИЧАЮТСЯ ЭКОКОЖИ МЕЖДУ СОБОЙ:

ПРИМЕНЕНИЕ ЭКОКОЖИ:

РЕКОМЕНДАЦИИ ПО ПЕРЕТЯЖКИ СИДЕНИЙ ЭКОКОЖЕЙ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ:

УХОД ЗА ЭКОКОЖЕЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ: |

||||||

|

|||||||

|

Экокожа Kомпаньон NEW Dakota BLACK

есть на складе данная позиция также представлена с перфорацией данная позиция также представлена без поролона КРАТКИЕ ДАННЫЕ ЭКОКОЖИ КОМПАНЬОН NEW НА ПОРОЛОНЕ 5мм:

ОПИСАНИЕ ЭКОКОЖИ:

ЧЕМ ОТЛИЧАЮТСЯ ЭКОКОЖИ МЕЖДУ СОБОЙ:

ПРИМЕНЕНИЕ ЭКОКОЖИ:

РЕКОМЕНДАЦИИ ПО ПЕРЕТЯЖКИ СИДЕНИЙ ЭКОКОЖЕЙ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ:

УХОД ЗА ЭКОКОЖЕЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ: |

||||||

|

|||||||

|

Экокожа Kомпаньон NEW Dakota BLACK с перфорацией

есть на складе данная позиция также представлена без перфорации данная позиция также представлена без поролона КРАТКИЕ ДАННЫЕ ЭКОКОЖИ КОМПАНЬОН NEW НА ПОРОЛОНЕ 5мм:

ОПИСАНИЕ ЭКОКОЖИ:

ЧЕМ ОТЛИЧАЮТСЯ ЭКОКОЖИ МЕЖДУ СОБОЙ:

ПРИМЕНЕНИЕ ЭКОКОЖИ:

РЕКОМЕНДАЦИИ ПО ПЕРЕТЯЖКИ СИДЕНИЙ ЭКОКОЖЕЙ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ:

УХОД ЗА ЭКОКОЖЕЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ: |

||||||

|

|||||||

|

Экокожа Kомпаньон NEW Nappa BLACK

есть на складе по качеству схожа с экокожей Компаньон данная позиция также представлена с перфорацией

КРАТКИЕ ДАННЫЕ ЭКОКОЖИ КОМПАНЬОН NEW:

ОПИСАНИЕ ЭКОКОЖИ:

ЧЕМ ОТЛИЧАЮТСЯ ЭКОКОЖИ МЕЖДУ СОБОЙ:

ПРИМЕНЕНИЕ ЭКОКОЖИ:

РЕКОМЕНДАЦИИ ПО ПЕРЕТЯЖКИ СИДЕНИЙ ЭКОКОЖЕЙ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ:

УХОД ЗА ЭКОКОЖЕЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ: |

||||||

|

|||||||

|

Экокожа Kомпаньон NEW Nappa BLACK

есть на складе по качеству схожа с экокожей Компаньон данная позиция также представлена без перфорации

КРАТКИЕ ДАННЫЕ ЭКОКОЖИ КОМПАНЬОН NEW:

ОПИСАНИЕ ЭКОКОЖИ:

ЧЕМ ОТЛИЧАЮТСЯ ЭКОКОЖИ МЕЖДУ СОБОЙ:

ПРИМЕНЕНИЕ ЭКОКОЖИ:

РЕКОМЕНДАЦИИ ПО ПЕРЕТЯЖКИ СИДЕНИЙ ЭКОКОЖЕЙ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ:

УХОД ЗА ЭКОКОЖЕЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ: |

||||||

|

|||||||

|

Экокожа Kомпаньон NEW Dakota ANTRACIT

есть на складе по качеству схожа с экокожей Компаньон данная позиция также представлена с перфорацией КРАТКИЕ ДАННЫЕ ЭКОКОЖИ КОМПАНЬОН NEW:

ОПИСАНИЕ ЭКОКОЖИ:

ЧЕМ ОТЛИЧАЮТСЯ ЭКОКОЖИ МЕЖДУ СОБОЙ:

ПРИМЕНЕНИЕ ЭКОКОЖИ:

РЕКОМЕНДАЦИИ ПО ПЕРЕТЯЖКИ СИДЕНИЙ ЭКОКОЖЕЙ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ:

УХОД ЗА ЭКОКОЖЕЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ: |

||||||

|

|||||||

|

Экокожа Kомпаньон NEW Dakota ANTRACIT

есть на складе по качеству схожа с экокожей Компаньон данная позиция также представлена без перфорации данная позиция также представлена без перфорации на поролоне КРАТКИЕ ДАННЫЕ ЭКОКОЖИ КОМПАНЬОН NEW:

ОПИСАНИЕ ЭКОКОЖИ:

ЧЕМ ОТЛИЧАЮТСЯ ЭКОКОЖИ МЕЖДУ СОБОЙ:

ПРИМЕНЕНИЕ ЭКОКОЖИ:

РЕКОМЕНДАЦИИ ПО ПЕРЕТЯЖКИ СИДЕНИЙ ЭКОКОЖЕЙ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ:

УХОД ЗА ЭКОКОЖЕЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ: |

||||||

|

|||||||

|

Экокожа Kомпаньон NEW Dakota DARK GREY

есть на складе по качеству схожа с экокожей Компаньон данная позиция также представлена с перфорацией КРАТКИЕ ДАННЫЕ ЭКОКОЖИ КОМПАНЬОН NEW:

ОПИСАНИЕ ЭКОКОЖИ:

ЧЕМ ОТЛИЧАЮТСЯ ЭКОКОЖИ МЕЖДУ СОБОЙ:

ПРИМЕНЕНИЕ ЭКОКОЖИ:

РЕКОМЕНДАЦИИ ПО ПЕРЕТЯЖКИ СИДЕНИЙ ЭКОКОЖЕЙ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ:

УХОД ЗА ЭКОКОЖЕЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ: |

||||||

|

|||||||

|

Экокожа Kомпаньон NEW Dakota DARK GREY

есть на складе по качеству схожа с экокожей Компаньон данная позиция также представлена без перфорации КРАТКИЕ ДАННЫЕ ЭКОКОЖИ КОМПАНЬОН NEW:

ОПИСАНИЕ ЭКОКОЖИ:

ЧЕМ ОТЛИЧАЮТСЯ ЭКОКОЖИ МЕЖДУ СОБОЙ:

ПРИМЕНЕНИЕ ЭКОКОЖИ:

РЕКОМЕНДАЦИИ ПО ПЕРЕТЯЖКИ СИДЕНИЙ ЭКОКОЖЕЙ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ:

УХОД ЗА ЭКОКОЖЕЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ: |

||||||

|

|||||||

|

Экокожа Kомпаньон NEW Dakota SAND

нет на складе, приход ожидается в конце апреля по качеству схожа с экокожей Компаньон данная позиция также представлена с перфорацией КРАТКИЕ ДАННЫЕ ЭКОКОЖИ КОМПАНЬОН NEW:

ОПИСАНИЕ ЭКОКОЖИ:

ЧЕМ ОТЛИЧАЮТСЯ ЭКОКОЖИ МЕЖДУ СОБОЙ:

ПРИМЕНЕНИЕ ЭКОКОЖИ:

РЕКОМЕНДАЦИИ ПО ПЕРЕТЯЖКИ СИДЕНИЙ ЭКОКОЖЕЙ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ:

УХОД ЗА ЭКОКОЖЕЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ: |

||||||

|

|||||||

|

Экокожа Kомпаньон NEW Dakota SAND

есть на складе по качеству схожа с экокожей Компаньон данная позиция также представлена без перфорации КРАТКИЕ ДАННЫЕ ЭКОКОЖИ КОМПАНЬОН NEW:

ОПИСАНИЕ ЭКОКОЖИ:

ЧЕМ ОТЛИЧАЮТСЯ ЭКОКОЖИ МЕЖДУ СОБОЙ:

ПРИМЕНЕНИЕ ЭКОКОЖИ:

РЕКОМЕНДАЦИИ ПО ПЕРЕТЯЖКИ СИДЕНИЙ ЭКОКОЖЕЙ:

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ:

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ:

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ:

УХОД ЗА ЭКОКОЖЕЙ:

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ: НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ: |

||||||

|

|||||||

|

Каталог Экокожа Компаньон

есть на складе размер образцов 100х150мм, 14 образцов, скреплены стяжкой, подписаны каталог отправляется хорошо запакованным в воздушно-пузырьковую пленку и коробку на каталоге нет никакой информации (название, телефон, адрес) о компании www.SHYMKA.ru С помощью каталога можно в живую подобрать нужный Вам материал. Также каталог позволяет продавать материалы под заказ. Просто киньте каталог в корзину и оформите заказ с доставкой в Ваш город. После получения каталога, подберите нужный Вам материал и аналогично оформите заказ. Каталог включает в себя следующие виды экокожи:

|

|

Каталог Экокожа ЧЕРНАЯ в полотне

есть на складе размер образцов 150х100мм, 25 образцов, скреплены стяжкой, подписаны каталог отправляется хорошо запакованным в воздушно-пузырьковую пленку и коробку на каталоге нет никакой информации (название, телефон, адрес) о компании www.SHYMKA.ru С помощью каталога можно в живую подобрать нужный Вам материал. Также каталог позволяет продавать материалы под заказ. Просто киньте каталог в корзину и оформите заказ с доставкой в Ваш город. После получения каталога, подберите нужный Вам материал и аналогично оформите заказ. Каталог включает в себя следующие виды экокожи:

|

КРАТКИЕ ДАННЫЕ ЭКОКОЖИ КОМПАНЬОН:

- ширина рулона 1,4м, толщина материала 1,4мм, производитель Китай

- состав: хлопок 30%, полиуретан 70%

- для удобства нарезаем рулончики по 15пог.м или 21кв.м

- заводские рулоны идут по 30пог.м или 42кв.м

- используется при температуре от -35 до +80 °С

- продается на отрез погонными метрами кратно 10см и рулонами; минимальный заказ 1пог.м; заказанный Вами материал перед отправкой наматывается на круглую тубу и тщательно запаковывается в несколько слоев воздушно-пузырьковой пленки

ХАРАКТЕРИСТИКИ ЭКОКОЖИ КОМПАНЬОН:

- состав: хлопок 30%, полиуретан 70%

- устойчивость к истиранию: более 100000 (сто тысяч) циклов (тест BS 5690 Мартиндейла)

- устойчивость к многократному изгибу после воздействия влаги и ультрафиолета: 300000-500000 (тристо - пятьсот тысяч) циклов (ГОСТ 8979-75 искусственное старение)

- устойчивость к истиранию: 1000 (одна тысяча) оборотов (методика "ЦНИИПИК")

- морозоустойчивость: 50000 (пятьдесят тысяч) циклов (ГОСТ 20876-75)

- цветоустойчивость к свету: 4 балла (хорошо) (тест ASTM D-3597)

- сигаретный тест - не воспламеняется (пройден по ISO 8191/188)

- воздухопроницаемость: 54 мл/кв.см. в час (ГОСТ 938.18-70)

- паропроницаемость: 1,3 мг/кв.см. в час (ГОСТ 22900)

- гигроскопичность: 6,0% (ГОСТ 8971-78)

- гипоаллергенна

ОПИСАНИЕ ЭКОКОЖИ:

- Экокожа - искусственная кожа, представляющая собой тонкую полиуретановую пленку, армированную слоем полиуретановой пены с трикотажной подложкой.

- Экокожа немного тянется в поперечном направлении и практически не тянется в продольном направлении.

- Если Вам нужно скрыть неровности и придать поверхности мягкость, то необходимо заказать экокожу либо уже триплированную поролоном со спанбондом, либо дополнительно пустить первым слоем поролон нужной толщины.

- Экокожа приятна на ощупь - мягкая, эластичная. Её свойства теплопроводности близки к древесине, коже, она «тёплая».

- Экокожа воздухо- и паропроницаема.

- Экокожа гигроскопична, то есть поглощает водяные пары.

- Экокожа неаллергенна, т.к. ничего из себя не выделяет в процессе эксплуатации.

ЧЕМ ОТЛИЧАЮТСЯ ЭКОКОЖИ МЕЖДУ СОБОЙ:

- Все представленные на нашем сайте экокожи очень хорошего качества и применяются в разных областях. Чем дороже экокожа, тем она лучше. Предлагаем Вам сперва приобрести каталоги с образцами нужных Вам экокож со скидкой 40%, подобрать наиболее подходящую по цвету, фактуре и качеству экокожу, а потом оформить на нее заказ.

- Экокожа Орегон - самая недорогая и самая покупаемая позиция из экокож! Несмотря на цену, экокожа Орегон обладает хорошей износостойкостью, а по внешнему виду не уступает дорогим аналогам.

- Экокожа Space и Vega - новинка в ассортименте экокож для мебели. По качеству схожа с экокожей Орегон.

- Экокожа Alba и Art Vision - высококачественная экокожа для мебели, которая также широко используется и в автотюнинге. Уникальная отделка придает материалу дополнительные качества, позволяющие расширить его дизайнерские возможности. Экокожа с хорошими гигиеническими и эксплуатационными свойствами, обеспечивающая максимальный комфорт. Материал светостоек, воздухопроницаем, обладает высокой устойчивостью к многократному изгибу, к истираемости и сопротивляемостью к царапинам. Применяется при пошиве авточехлов и автомобильных сидений.

- Экокожа Кордова - новый высокотехнологичный вид экокожи. Как и любая другая экокожа, данный материал по своему внешнему виду и тактильным свойствам максимально приближен к натуральной коже. Главной особенностью Экокожи Кордова является специальное покрытие EASY CLEAN, обеспечивающее легкую чистку от большинства бытовых загрязнений, включая следы от шариковых ручек. Для удаления чернил достаточно просто потереть кожу обычной бумажной салфеткой. Именно поэтому Экокожа Кордова отлично подходит для перетяжки мебели, перетяжки салона автомобиля и пошива качественных авточехлов. По своим эксплуатационным характеристикам Экокожа Кордова заметно превосходит Экокожу Орегон, однако все же уступает в прочности Экокоже на микрофибре.

- Экокожа Крит - высокотехнологичная искусственная кожа с повышенной износостойкостью: до 200 000 циклов по тесту Мартиндейла. Это в несколько раз больше, чем у бюджетных экокож и фактически по показателям износостойкости она соответствует экокоже на микрофибре. Тем не менее экокожа Крит не имеет подложки из микрофибры, поэтому она не так устойчива к порезам и механическим повреждениям. Область применения экокожи Крит: перетяжка салонов авто, домашней, промышленной и общественной мебели.

- Экокожа Компаньон отличается от экокожи Орегон, Alba и Art Vision более износостойкой и долговечной полиуретановой пленкой в лицевом слое, которая сверхустойчива к царапинам. Экокожа Компаньон имеет такой же лицевой слой, что и экокожа на Микрофибре, но отличается тем, что полиуретановая пленка нанесена не на микрофибру, а на полиуретановую пену с тканевой ворсистой подложкой. Если экокожу на Микрофибре используют для полной перетяжки сидений салона автомобиля, то экокожу Компаньон в основном используют для обтяжки спинок сидений, для пошива чехлов и перетяжки не сильно изогнутых деталей салона автомобиля.

- Экокожа Стрейч отличается мягкостью и пластичностью, что позволяет использовать ее при пошиве верхней одежды - курток, плащей, а также костюмов, юбок, брюк. Также ее широко используют для пошива сумочек и аксессуаров.

- Из всего ассортимента экокожи, только экокожа Орегон и экокожа на Микрофибре представлена в исполнении с перфорацией.

ПРИМЕНЕНИЕ ЭКОКОЖИ:

- Экокожа в основном используется для пошива чехлов и перетяжки сидений салона легковых автомобилей, микроавтобусов, автобусов, сидений грузовых автомобилей и различной спецтехники.

- Применяется для перетяжки дверных карт, рычага коробки передач, подиума, акустической полки, элементов панели салона автомобиля.

- Внимание, для профессиональной перетяжки сидений и дверных карт салона автомобиля в 90% случаях мастера тюнинг-ателье используют экокожу на Микрофибре. Она имеет такую же толщину, что и натуральная кожа в шкурах, а по качеству и разнообразию цветов и фактур экокоже на Микрофибре нет равных!

- Если нужно перетянуть руль или ручку кпп, то рекомендуем использовать серию SW для рулей. Экокожу на микрофибре Швайцер БМВ, Швайцер Наппа и Dakota многие мастера также используют для перетяжки руля и ручки кпп, но под свою ответственность.

- Применяется для обтяжки различных обшивок в салоне микроавтобуса, автобуса, в кабине грузовых машин и различной спецтехники.

- Перетяжка мебели для дома.

- Перетяжка мебели для офиса.

- Перетяжка детской мебели.

- Перетяжка спортивных тренажеров.

- Пошив игрушек.

- Пошив сумочек.

РЕКОМЕНДАЦИИ ПО ПЕРЕТЯЖКИ СИДЕНИЙ ЭКОКОЖЕЙ:

- Под любую экокожу необходимо подкладывать поролон на подложке, который желательно при перетяжке сидений приклеивать к экокоже. Для этих целей рекомендуем использовать аэрозольный клей Fensol 60 Fentac Adhesives или Tuskbond.

- Какой поролон использовать, на сетке или на спанбонде? Специалисты в области перетяжки автомобильных сидений рекомендуют использовать именно поролон на сетке, которая обладает большей прочностью, нежели спанбонд.

- Экокожу для средних вставок спинки и сидения, как правило, дублируют поролоном на сетке толщиной 10мм, а боковые поддерживающие элементы спинки и сидения - поролоном на сетке толщиной 5мм.

- Для Вашего удобства в ассортименте экокожи на нашем сайте есть экокожа Орегон на поролоне с подложкой. Поролон с подложкой в виде сетки или спанбонда уже наклеен к экокоже Орегон клеевым методом, что позволяет сразу использовать сэндвич при перетяжке, а не приклеивать поролон к экокоже.

СПОСОБЫ ОБТЯЖКИ ДЕТАЛИ ЭКОКОЖЕЙ:

- Лицевая часть детали обтягивается экокожей с загибом на внутреннюю сторону. С внутренней стороны экокожа крепится при помощи степлера. По необходимости под нее стелится поролон нужной толщины.

- Из экокожи шьется чехол согласно форме детали. Готовый чехол натягивается на деталь и стягивается с внутренней стороны детали резинками или веревками.

- Экокожа клеится на поверхность детали при помощи аэрозольного клея.

- Экокожа клеится на поверхность детали при помощи жидкого клея.

КЛЕЯ ДЛЯ НАКЛЕЙКИ ЭКОКОЖИ:

- Для наклейки экокожи на поверхности, не подвергающиеся воздействию температуры выше 50°С рекомендуем использовать клея: Все эти клея не держат температур более 50°С, поэтому их в основном используют для обтяжки экокожей таких деталей салона автомобиля, как акустическая полка, обшивки дверей, подиумы, сабвуфер.

- Для наклейки экокожи на поверхности, подвергающиеся воздействию температуры выше 50°С рекомендуем использовать термоустойчивые клея:

- Клей SAR 30-E

КАК ПРАВИЛЬНО НАКЛЕИТЬ ЭКОКОЖУ:

- Все способы, которые приведены ниже, относятся к наклейке экокожи.

- Предварительно нужно отмерить и отрезать необходимый кусок материала. Затем его следует разложить на оклеиваемую поверхность и распланировать ход наклейки (учесть поэтапность наклейки, все изгибы поверхности, временные интервалы).

- Склеиваемые поверхности необходимо зачистить и высушить.

- Гладкие пластиковые поверхности желательно предварительно зачистить мелкой шкуркой (зернистость 100) для лучшего сцепления с клеем.

- Рабочую поверхность нужно обезжирить разбавителем-очистителем Молекула или другими обезжиривателями.

- Если рабочая поверхность представляет собой пластик, на котором указана маркировка PP/PE или другая маркировка, то перед нанесением клея нужно обработать такую поверхность антисиликоном и грунтом по пластику, чтобы клей не отслаивался от пластика.

- Если на рабочей поверхности уже установлен какой-то старый материал, то сдирать его или нет, решать Вам. Можно наклеить новый материал прям на старый материал. Рекомендуем попробовать наклеить небольшой кусок и решить, стоит снимать старый материал или нет.

- В ЗАВИСИМОСТИ ОТ КЛЕЯ, СПОСОБ НАКЛЕЙКИ ОТЛИЧАЕТСЯ:

- Если Вы выбрали жидкий клей Мебельный, 88 или Молекула Термостойкий, то необходимо нанести клей тонким слоем на обе поверхности кисточкой, валиком или при помощи пульверизатора с расстояния не менее 30-40см (диаметр дюзы 2,5-3 мм, давление воздуха не менее 4 атмосфер), выждать, пока из клея частично выветрится растворитель, после чего необходимо прижать экокожу к поверхности и ненадолго зафиксировать. Клей наносится на обе склеиваемые поверхности равномерно, без пропусков. Не допускайте сильного пропитывания клеем изнанки экокожи. Окончательное склеивание данными жидкими клеями происходит в течение 24 часов. Можно на саму экокожу клей и не наносить, если она и так хорошо приклеивается.

- Если Вы выбрали один из аэрозольных клеев (самый распространенный способ), то нужно распылить клей на рабочую поверхность и на изнанку экокожи, выждать, пока из клея частично выветрится растворитель, после чего необходимо прижать экокожу к поверхности и ненадолго зафиксировать. Окончательное склеивание аэрозольными клеями происходит в течение 24 часов. Можно на саму экокожу клей и не наносить, если она и так хорошо приклеивается. Внимание, со 100% гарантией экокожу к рабочей поверхности приклеит только клей Scotch-Weld 3M 90. Остальные аэрозольные клея, приведенные выше, также применяются для наклейки экокожи, но, почему-то, по ним иногда бывают нарекания. Решать Вам.

- Если Вы выбрали термоактивируемый клей Молекула ТермоАктивный, KLEYBERG 900-И, Poligrip, SAR 306, SAR 30-E, то наклейка экокожи происходит намного сложнее и при помощи фена. Клей наносится на обе склеиваемые поверхности либо пульверизатором с расстояния не менее 30-40см (диаметр дюзы 2,5-3 мм, давление воздуха не менее 4 атмосфер), либо тонким слоем кисточкой (валиком). Клей наносится на обе склеиваемые поверхности равномерно, без пропусков. Не допускайте сильного пропитывания клеем изнанки экокожи. Из пульверизатора клей наносится не менее, чем в пять тонких слоев. Каждый последующий слой наносится после высыхания предыдущего слоя. Время высыхания каждого слоя 20-30 минут. После высыхания последнего слоя, экокожа (с нанесенным на нее клеевым слоем) укладывается на рабочую поверхность (обшивку), которая в свою очередь тоже покрыта клеевым слоем. Так как клей на рабочей поверхности и на экокоже после высыхания не обладает липкостью, то две поверхности не склеиваются при наложении друг на друга. Это очень удобно, так как позволяет разложить экокожу с нанесенным на неё клеевым слоем на рабочую, покрытую клеем поверхность и предвидеть, распланировать пошаговый процесс приклеивания. После того, как экокожа разложена, клей на рабочей поверхности и на экокоже активируется (нагревается) небольшими участками промышленным (профессиональным) феном до появления липкости, после чего экокожа разглаживается и прижимается к рабочей поверхности. Прижимать экокожу нужно до тех пор, пока температура клея не упадет и обе поверхности не склеются между собой. Чтобы активировать клей, нужно или непосредственно нагревать клей с изнаночной стороны экокожи, или нагревать саму экокожу с лицевой стороны. Экокожа в трудных местах дополнительно прогревается феном. Таким образом, участок за участком, происходит склеивание по всей поверхности. В этом и заключается удобство пошаговой наклейки экокожи при помощи термоактивируемого клея. Расстояние от сопла фена до клеевого слоя и температура выбираются таким образом, чтобы не сжечь экокожу и в тоже время активировать (разжижить) клей. Во избежании ожогов, пользуйтесь защитной перчаткой. Особые подвергнутые нагрузке места обрабатываются клеем дополнительно. При нанесении клея тонкими слоями, клей толщины не дает. Если вы обнаружили не проклеенное место, клей позволяет исправить данный дефект повторным нагревом данного участка.

- Рекомендуем попробовать наклеить сперва небольшой кусок экокожи, набраться немного опыта, а затем перейти к полной наклейке. Суть приклейки экокожи состоит в том, чтобы клей слегка впитался в подложку и в рабочую поверхность, затем, после прижатия экокожи к рабочей поверхности, произошло прочное склеивание двух поверхностей. Перед наклейкой внимательно прочтите инструкции по применению соответствующего клея на нашем сайте в разделе клея.

УХОД ЗА ЭКОКОЖЕЙ:

- НИКАКОЙ ХИМЧИСТКИ для экокожи!!! Начнет облезать либо сразу после химчистки, либо немного позже. Лицевой полиуретановый слой разрушается при химчистке. Химчистка также разрушает связь лицевого полиуретанового слоя с основанием.

- Для удаления бытовых загрязнений (чай, кофе, сок, пыль и т.д.) поверхность экокожи нужно обработать увлажненной мягкой тканью легкими движениями, затем обязательно протереть насухо. Таким же способом удаляются пыльный налет и грязь. Если не удалось избавиться от загрязнения сразу, допускается использование 40-50% спиртово-водного раствора или нашатырного спирта.

- Со временем кожаная обивка под воздействием солнечных лучей, влажности, температуры и прочего воздействия усыхает, теряет эластичность и внешний вид, вытирается, вытягивается или начинает рваться по швам, а на поверхности кожи образуются трещины, которые забиваются грязью. Чтобы избежать подобных неприятностей и как можно дольше сохранить целостность экокожи, необходимо использовать специальный очиститель-кондиционер для искусственной кожи. Обрабатывать экокожу таким средством нужно раз в месяц летом и раз в три месяца зимой.

- Если поверхность обтянута белоснежной экокожей или экокожей светлых тонов, то для лучшей защиты изделия от загрязнения (например джинсы могут «подкрасить» кожаную обивку мебели красителем, от которого невозможно избавиться) рекомендуется применять специальную водо- и грязеотталкивающую пропитку TARRAGO для экокожи. Пропитка наносится в несколько слоев на сухую и очищенную поверхность с расстояния 30см. Обработку необходимо повторять после каждой чистки изделия из экокожи. ВНИМАНИЕ. Перед применением пропитки протестируйте ее на скрытом участке изделия.

- Категорически не рекомендуется оставлять экокожу мокрой после процедур ухода и чистки. Это приведёт к частичному разрушению полимерной плёнки, и, как следствие, к преждевременной потере первоначального внешнего вида экокожи.

- Последнее время всё чаще экокожу в салоне автомобиля протирают влажными салфетками. Этого делать ни в коем случае нельзя! В состав раствора, которым увлажнены салфетки, входят компоненты, которые разрушают экокожу. Достаточно протереть экокожу мягкой тканью, смоченной обычной чистой водой.

- Внимание!!! Ни в коем случае нельзя использовать для чистки экокожи растворители и абразивные чистящие средства!!!

НУЖНОЕ ДЛЯ ПЕРЕТЯЖКИ ЭКОКОЖЕЙ:

НУЖНОЕ ДЛЯ ПЕРЕПРОДАЖИ ЭКОКОЖИ: